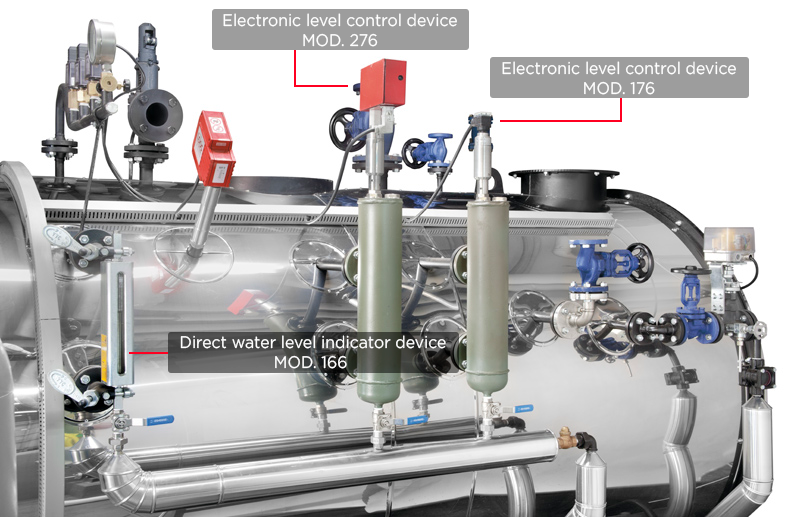

Water level control systems for steam boilers

One of the most important safety elements for steam boilers operation has always been the water level control. The technological development has allowed improving the safety in the steam boilers operation with the evolution of this control, from the first manual controls to the current electronic systems. The current Pressure Equipment Directive 2014/68/UE and the specific requirements for flame-tube smoke-tube boilers (EN12953) or water-tube boilers (EN12952), at least, establish minimum requirements needed for permitting a boiler operation without permanent supervision.

A common element to all boilers configurations, also available for tanks and, in short, for any pressure vessel, is the visual level control device (indicator):

Direct water level indicator device

MOD. 166 EN ASME/ANSI

For boilers, vessels, tanks, reservoirs, etc., to indicate the level of liquids, gases and steam.

A multiple-slot polyprismatic reflection glass allows the level to be optically read, clearly differentiating liquid and gas phases.

Electronic level control devices are used for automation of level control in new steam boilers and containers, tanks, etc. And even for the modernization or retrofitting of existing equipment. The two most common types of these devices are the conductive and the capacitive ones, depending on the technology used for the measurement.

Conductive level control devices (Mod. 176 EN ASME/MNPT) allow (by conductivity difference between the liquid phase and the vapor phase) to control low level, very low level, maximum level, pump start or stop, with a level electrode (176-EN) or (176-ES) in each case.

Electronic level control device

MOD. 176 EN ASME/MNPT

This device guarantees automatic, safe and reliable control, regulation and signaling of the level of liquids in: steam boilers, pressurized vessels, preheaters, processes, etc.

On the other hand, the capacitive control devices (Mod. 276 EN ASME/MNPT) allow a continuous control of the water level, controlling a feed pump or a control valve through the corresponding regulator, and at the same time to establish maximum or minimum level limits. This capacitive device, in conjunction with the conductors established as minimum and/or maximum redundant level safety, allows boilers operation without permanent supervision with intervals of 24 hours or longer.

MOD. 276 EN ASME/MNPT

This device, when combined with a motorized valve, ensures the continuous control and display of the level, with a high and low level alarm for: steam and hot water boilers, autoclaves, pre-heaters, pressured vessels, condensation and feed water tanks, processing, etc.

In the upper image of this entry, there is a steam boiler equipped with the described devices.